HT/High Temperature Drilling Starch

- Home

- Products & Services

- HT/High Temperature Drilling Starch

The High-Temperature Drilling starch is a polymer derived from the unmodified starch including amylopectin content. It has epichlorohydrin and viscosity that reaches the maximum value. This starch has fermentation stability and can be hydroxypropylated. It gives enhanced high-temperature fluid loss performance when working in combination with drilling fluids.

The High-Temperature Drilling starch is also used in other applications. Offered with a high-temperature tolerance, it is apt for drilling, work-over, or completion fluid loss and works as a control additive appropriate for its utilization in high temperatures. It has optimal use in all water-based drilling, stimulation, and completion fluids. This starch can meet all industrial standards.

Technical Specifications

| S.No | Parameters | UOM | Limits |

|---|---|---|---|

| Suspension Properties | |||

| 1 | In 40 g/lit salt water | Cps Max | 18 |

| 2 | In saturated salt water | Cps Max | 20 |

| Filtrate volume | |||

| 1 | In 40 g/lit salt water | ml Max | 10 |

| 2 | In saturated salt water | ml Max | 10 |

| 3 | Residue greater than 2000 μm | No residue | |

| 4 | Moisture | % Max | 10 |

Packing

- 50 Kgs & Jumbo Bags | As per specific requirement(s).

- Packed in printed PP woven bags.

Applications

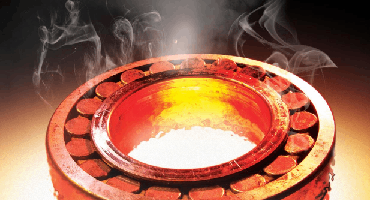

High Temperature

High temperatures help in stabilizing rheology.

Ferment Process

Does not ferment Treatment Rate, Typical.

Higher Temperatures

Higher temperatures (above 150°F) may be needed to “activate” HT Starch to supply effective rheology and fluid loss control totally as a binding agent.

Liquid Loss

1 – 4 ppb, as essential to control liquid loss.