Why Your Yarn Breaks in Loom – 7 Reasons & How Thin Boiling Starch Solves It

Introduction

Yarn breakage in the loom is one of the most common and frustrating challenges faced by textile mills worldwide. Whether it’s a high-speed automatic loom or a manual powerloom, yarn breakage leads to significant downtime, increased labor costs, and compromised fabric quality. But what causes yarn to break, and how can this issue be resolved?

While several factors contribute to this problem, the right choice of sizing starch—particularly Thin Boiling Starch (TBS)—can significantly reduce the risk of yarn breakage and improve weaving efficiency. In this blog post, we’ll discuss seven key reasons for yarn breakage in looms and how Thin Boiling Starch can help solve this issue.

1. Poor Yarn Strength and Quality

The Problem:

Yarn that is weak or of poor quality is highly susceptible to breakage during weaving. Poorly spun fibers, irregular yarn thickness, and yarns with weak tensile strength are more prone to snapping under the tension of the loom.

How Thin Boiling Starch Helps:

Thin Boiling Starch (TBS) plays a crucial role in strengthening yarns by forming a smooth, protective coating around the fibers. This coating enhances the yarn’s overall tensile strength, making it more resistant to breakage. TBS improves yarn elasticity, reducing the risk of snapping under the pressure and friction of high-speed looms.

By using a high-quality TBS formulation, mills can prevent premature breakage of yarns, even in challenging weaving conditions.

Key Characteristics of an Ideal Starch for Powerloom Use

The Problem:

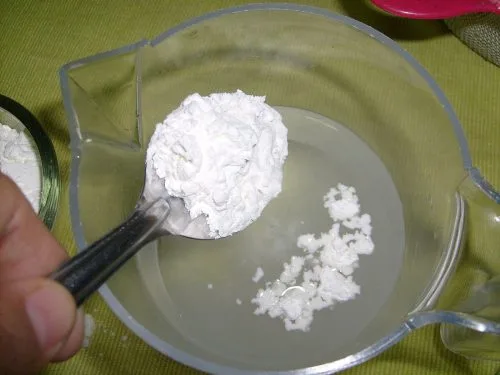

Sizing is the process of coating yarn with a protective layer of starch, which provides strength, lubricates the fibers, and ensures smooth weaving. However, incorrect sizing procedures—such as improper starch concentration, incorrect cooking temperatures, or uneven application—can lead to inadequate yarn protection, causing breakage during weaving.

How Thin Boiling Starch Helps:

Thin Boiling Starch (TBS) is specifically designed to have low viscosity, which allows it to penetrate the yarn more effectively during the sizing process. With its ability to form a uniform coating on the yarn, TBS ensures that the yarn is adequately sized, preventing friction-related breakages.

Moreover, TBS can be used with automatic sizing machines to maintain consistent viscosity and application rates, ensuring that the sizing process is optimized for the best results and minimizing yarn breakage.

3. High Friction Between Yarn and Loom Parts

The Problem:

During the weaving process, yarns pass through various parts of the loom, such as the reed, heddles, and shuttle. These components can generate significant friction, which causes yarns to weaken, stretch, and eventually break.

How Thin Boiling Starch Helps:

One of the key properties of Thin Boiling Starch is its ability to reduce friction during the weaving process. When applied to yarn, TBS forms a smooth, lubricating film that significantly reduces friction between the yarn and loom components. This lubrication helps prevent excessive wear on the yarn, reducing the likelihood of breakage even in high-speed weaving operations.

By using TBS, mills can increase weaving efficiency, reduce downtime, and improve the longevity of both the yarn and loom.

4. Inconsistent Yarn Tension

The Problem:

Inconsistent tension on the warp yarns during weaving can cause them to stretch unevenly, leading to breakage. Whether it’s caused by improper tensioning equipment or fluctuating machine settings, inconsistent tension puts undue stress on the yarn, causing it to snap.

How Thin Boiling Starch Helps:

Thin Boiling Starch helps by providing a uniform coating that stabilizes yarn tension during the weaving process. The starch coating adds an additional layer of strength and rigidity to the yarn, reducing its susceptibility to stretching or snapping under fluctuating tension.

With consistent yarn strength, mills can ensure that the yarn maintains its integrity, even during high-speed operations, leading to fewer breakages and smoother weaving.

5. Yarn Hairiness

The Problem:

Yarn hairiness refers to the formation of fuzzy, protruding fibers that project out from the yarn bundle. These fibers can get caught in the loom, causing friction, uneven fabric texture, and frequent yarn breakages.

How Thin Boiling Starch Helps:

Thin Boiling Starch helps control yarn hairiness by creating a smooth, uniform coating on each fiber. This reduces the likelihood of fiber protrusion and minimizes the chances of yarns becoming tangled in the loom. Additionally, the starch film provides a protective layer that prevents the fibers from becoming overly rough, further reducing the chances of breakage due to yarn hairiness.

By using high-quality TBS, mills can improve the appearance of the fabric and reduce yarn breakage caused by hairiness.

6. Low-Quality Starch or Improper Starch Selection

The Problem:

Using low-quality starch or selecting the wrong type of starch for sizing can lead to poor adhesion, weak film formation, and ineffective lubrication. When the starch doesn’t properly coat the yarn, it fails to provide the necessary strength and flexibility, causing yarn breakage during weaving.

How Thin Boiling Starch Helps:

Thin Boiling Starch (TBS) is specifically designed for high-speed weaving applications. It provides excellent penetration and a smooth coating that adheres well to the yarn. The starch film formed by TBS is both strong and flexible, providing the necessary protection and lubrication for the yarn.

By using high-quality TBS, mills ensure that they are using the most effective starch to reduce yarn breakage, ensuring smooth and efficient weaving.

7. Loom Speed and Machine Settings

The Problem:

High-speed looms are great for maximizing production, but they also place more strain on the yarns. As loom speed increases, the tension and friction on the yarn increase, making breakage more likely. If the machine settings aren’t properly calibrated to handle high speeds, the risk of breakage escalates.

How Thin Boiling Starch Helps:

Thin Boiling Starch is perfect for high-speed looms because it forms a low-viscosity, highly effective film that protects the yarn under high tension. Its excellent lubrication properties reduce friction and wear, allowing the yarn to withstand faster weaving speeds without breaking.

When using TBS, mills can run high-speed looms with greater efficiency, ensuring that the yarn remains strong and durable even at the highest speeds.

SPAC: A Trusted Maize Starch Manufacturer for Looms

As one of India’s leading maize starch manufacturers, SPAC has earned a reputation for producing top-quality Thin Boiling Starch (TBS) that meets the stringent demands of the textile industry. SPAC’s maize-based starch is designed to enhance the performance of yarns in powerlooms, reducing breakage and improving fabric quality.

By choosing SPAC’s TBS, mills gain access to a reliable solution that boosts weaving efficiency, reduces downtime, and enhances fabric quality. SPAC ensures consistent viscosity, superior film formation, and excellent penetration, providing yarns with the protection they need to perform optimally in high-speed looms.

SPAC: Leading Tapioca Starch Suppliers in India

SPAC: The Brand You Can Trust for Quality Starch Solutions

When it comes to choosing the right starch to prevent yarn breakage in looms, SPAC is the brand that textile mills trust. As a leader among maize starch manufacturers and tapioca starch suppliers in India, SPAC offers a comprehensive range of high-performance starch products that ensure superior weaving performance, minimize yarn breakage, and enhance fabric quality.

Whether you need maize-based Thin Boiling Starch or tapioca starch solutions, SPAC provides top-notch products tailored to your specific needs. By using SPAC’s starch, mills can achieve higher productivity, reduced yarn wastage, and a smoother weaving process.